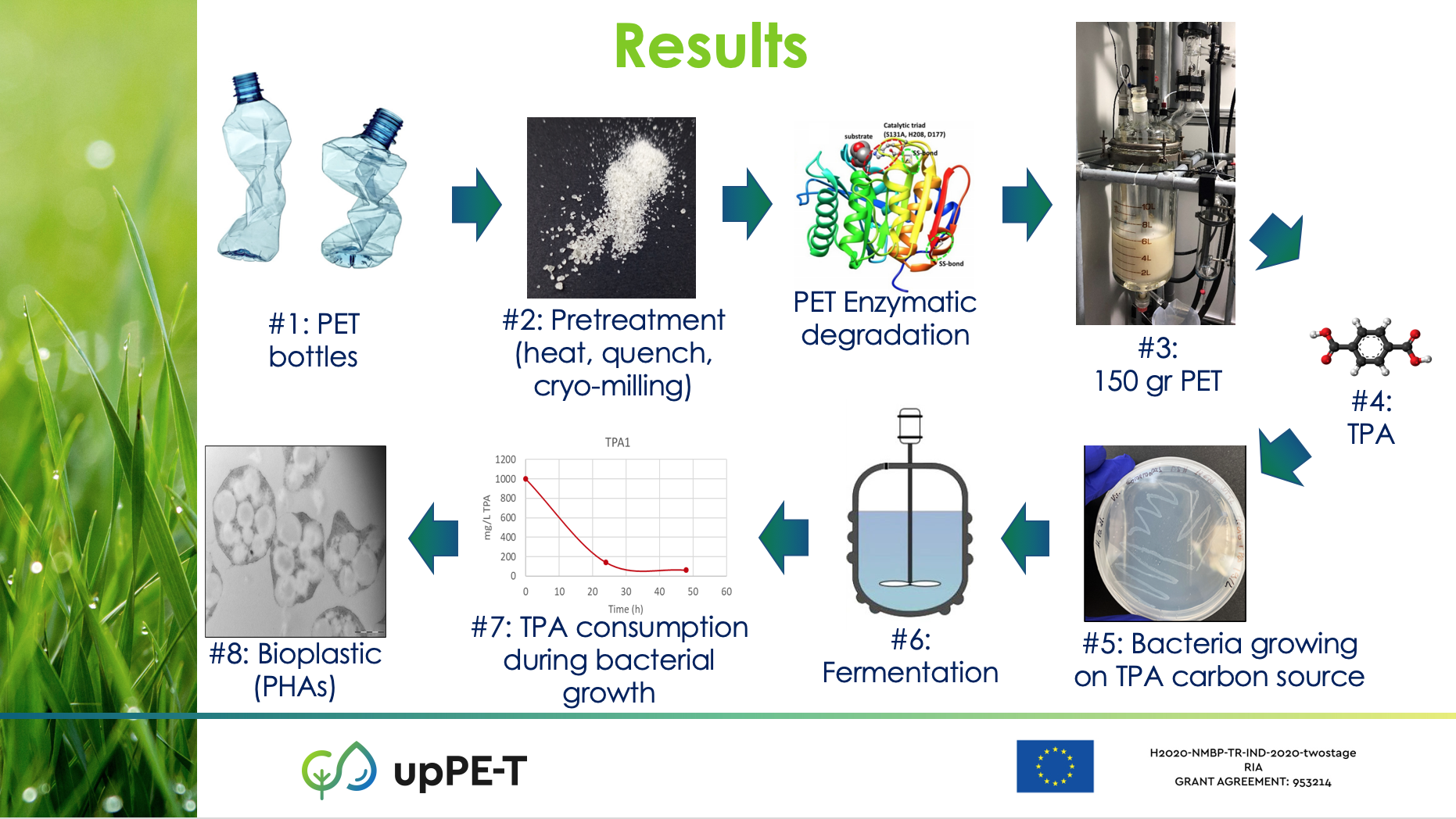

In the first two years of its implementation upPE-T team has generated quite some results:

#1: the team has collected different kinds of PET wastes and studied chemical properties and learned what the important aspects for enzymatic degradation are, like the level of crystallinity in the PET material.

#2: the team has looked at a variety of methods to pre-treat the PET to make the material more amenable to enzymatic attack. Granulation helps, but a heat treatment followed by cold shock works best so far.

#3: the team has scaled the conversion of PET waste to 150 gram portions. After enzymatic reaction, there is no plastic material left and it is all converted into terephthalic acid (TPA) and ethylene glycol (EG).

#4: the TPA was isolated and analyzed and did not contain any impurities so the team could use it in the next step.

#5: the team selected bacteria that can grow on TPA as a sole carbon source. These organisms break the TPA down into metabolites that facilitate the formation of biomass.

#6: the team developed fermentation conditions that are optimal for producing as much biomass as possible by adding other required nutrients like spore elements and nitrogen.

#7: as can be seen, the TPA disappears rather quickly in the first hours of the fermentation.

#8: the biomass is then used in a different fermentation, now with an organism that produces PHBV bioplastics which can be seen as the small globules that are contained within the cell.

Next experiments will be aimed at making more bioplastics, and scaling all the processes to a larger scale to enable project partners to do their bioplastic materials development. and wet lab experimentation. PE degradation must go via an oxidative pathway and we expect the products of PE degradation to be aliphatic alcohols/aldehydes/acids. These mixtures will serve (after modification, if required) as a growth substrate in the fermentations of an organism that naturally produces polymers like polyhydroxybutyrate and/or polyhydroxyvalerate (combined they are called PHBV).

#1: the team has collected different kinds of PET wastes and studied chemical properties and learned what the important aspects for enzymatic degradation are, like the level of crystallinity in the PET material.

#2: the team has looked at a variety of methods to pre-treat the PET to make the material more amenable to enzymatic attack. Granulation helps, but a heat treatment followed by cold shock works best so far.

#3: the team has scaled the conversion of PET waste to 150 gram portions. After enzymatic reaction, there is no plastic material left and it is all converted into terephthalic acid (TPA) and ethylene glycol (EG).

#4: the TPA was isolated and analyzed and did not contain any impurities so the team could use it in the next step.

#5: the team selected bacteria that can grow on TPA as a sole carbon source. These organisms break the TPA down into metabolites that facilitate the formation of biomass.

#6: the team developed fermentation conditions that are optimal for producing as much biomass as possible by adding other required nutrients like spore elements and nitrogen.

#7: as can be seen, the TPA disappears rather quickly in the first hours of the fermentation.

#8: the biomass is then used in a different fermentation, now with an organism that produces PHBV bioplastics which can be seen as the small globules that are contained within the cell.

Next experiments will be aimed at making more bioplastics, and scaling all the processes to a larger scale to enable project partners to do their bioplastic materials development. and wet lab experimentation. PE degradation must go via an oxidative pathway and we expect the products of PE degradation to be aliphatic alcohols/aldehydes/acids. These mixtures will serve (after modification, if required) as a growth substrate in the fermentations of an organism that naturally produces polymers like polyhydroxybutyrate and/or polyhydroxyvalerate (combined they are called PHBV).